pROCESS

We Research Every Product From the Ground Up

| Category | Capacity / Area | Category | Capacity / Area |

| Cold Storage 1 | UP to – 20~30℃ / 331.09㎡ / 180ton | Loading Area | HYUNDAI 1.8-ton forklift, 3-level, 6.5M |

| Cold Storage 2 | UP to – 20~30℃ / 159.56㎡ / 96ton | Hygiene Control Room | Industrial air curtain & hygiene equipment |

| Cold Storage 3 | UP to – 20~30℃ / 108.33㎡ / 42ton | Preprocessing Room | Conveyor washer, filleting table, cutting boards, etc. |

| Cold Storage 4 | UP to – 20~30℃ / 104.08㎡ / 48ton | Grilling Room | Fish grilling machine, far-infrared grill, etc. |

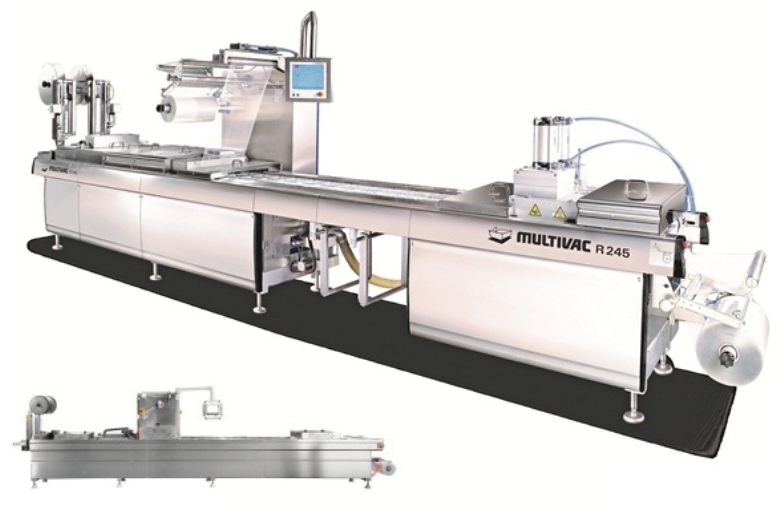

| Cold Storage 5 | UP to – 20~30℃ / 96.82㎡ / 42ton | Inner Packaging Room | Thermoforming packing machine, metal detector, etc. |

| Cold Storage 6 | UP to – 20~30℃ / 79.24㎡ / 36ton | Outer Packaging Room | Ice box packing machine, etc. |

| Loading Dock 1 | TOYOTA 2-ton forklift, cab type | Quick Freezing Room | Up to -60°C |

| Loading Dock 2 | TOYOTA 2-ton forklift, 3-level, 5M | Cutting / Filleting Room | Raw material processing table, etc. |